COMPANY OVERVIEW

Zero Carbon Technologies Limited (“Zero Carbon” or “the Company”) is a business entity incorporated in Great Britain and Wales in the year 2021 with plans to build and operate a battery recycling plant in La Mancha Province, Spain which will provide circular critical metals recovery from EV LI Ion and lead batteries.

Electric-vehicle demand is accelerating rapidly and so is the need for EV batteries. As these batteries reach end-of-life, significant growth opportunities in the recycling space are emerging. Zero Carbon’s patented and proprietary low-CO2 battery recycling solutions makes it possible to recycle over 80% of the battery, and 95% of the valuable metals contained in the black mass from its patented and proprietary procedures. The company has a significant opportunity due to a current critical metal shortage in current markets and is revolutionising the lead and lithium-ion battery value chain for electric vehicle and industrial use batteries.

About Zero Carbon Technologies

About

Our Mission

Our Vision

Zero Carbon is a circular economy innovator with specific focus on recycling

technologies, particularly for end-of-life management of batteries.

Our Vision

Our Mission

Our Vision

To be the EU’s Market leader in waste battery reuse, recycling and recovery and build a business model that can be replicated across Europe and influence a global paradigm shift in how battery waste is managed and recycled to encourage and grow the circular economy.

Our Mission

Our Mission

Our Mission

TO REVOLUTIONIZE RECYCLING

and connect a web of industries where one stream's waste is another stream's

in-feed by bridging linear and wasteful processes

to create a circular, pollution-free, zero-waste future.

THE PROBLEM

Global demand for EV batteries is increasing

Global demand for EV batteries is increasing

Global demand for EV batteries is increasing

EVs may be more than 60% of all vehicles with over 300 million electric vehicles on the world’s roads by 2030.

International Energy Agency

Growth of Mining & Production

Global demand for EV batteries is increasing

Global demand for EV batteries is increasing

The entire lithium-ion (Li-ion) battery chain, from mining through recycling, could grow by over 30 percent annually from 2022 to 2030.

American Chemical Society

Carbon Emissions from Mining

Waste -Only 5% of lithium-ion batteries are recycled

Waste -Only 5% of lithium-ion batteries are recycled

In hard rock mining, for every ton of mined lithium,

15 tons of CO2are emitted into the air.

MIT Climate Portal

Waste -Only 5% of lithium-ion batteries are recycled

Waste -Only 5% of lithium-ion batteries are recycled

Waste -Only 5% of lithium-ion batteries are recycled

There are dramatic environmental and financial implications for the projected 8 million tons of waste.

CAS Science Team

OUR SOLUTION

Zero Carbon will undertake battery mineral recovery*, a recycling mechanism, to become part of the circular economy that reuses important resources.

*Battery Mineral Recovery is the retrieval of commercially important metal ions like Co and Li from spent batteries and is advantageous considering the limited availability of metal ions and environmental regulations.

OUR SERVICES

- Non-extractive mining means recycling products from mining tailings or black mass.

- Circular Recycling is where materials are collected, recycled and returned to producers to be reused as ingredients in new products.

OUR APPROACH

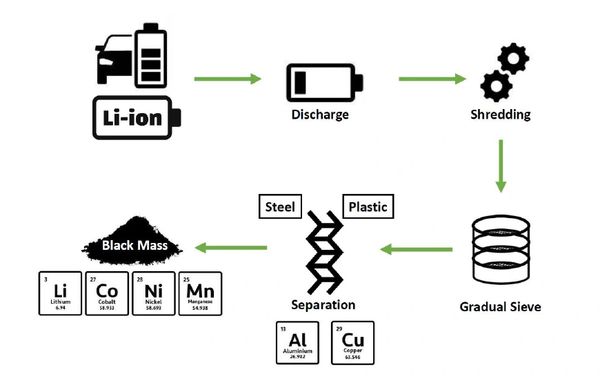

FRONT-END PROCESSING: FROM BATTERY PACK TO BLACK MASS

Zero Carbon’s advanced system, perfected through in-house engineering and collaboration with its technology partner REGENERATE (Regenerate’s research spun out of the University of Cambridge, UK. ), offers swift manufacturing, installation, and commissioning, all achievable within a span of just nine months from the date of instruction.

Advantages of Circular Economy Approaches in Battery Recycling and Engineering Recyclable Batteries

The increasing demand for energy storage solutions, driven by the rise in electric vehicles and renewable energy sources, has intensified the focus on sustainable practices within the battery industry. This paper explores the advantages of adopting circular economy principles in battery recycling, emphasizing the engineering of batteries to be completely recyclable. Additionally, it delves into the potential benefits of up-cycling recycled batteries to surpass the performance of new batteries.

Contact Us

Zero Carbon Technologies

71-75 Shelton Street, Covent Garden London, WC2H 9JQ

chris@zerocarbontechnologies.es UK: +44 (20) 8834 0015 Int: +1 604 250 1060

Subscribe

Zero Carbon Technologies Ltd

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.