Zero Carbon is a circular economy innovator with specific focus on recycling technologies, particularly for end-of-life management of batteries. The company was founded on May 26, 2021, and has secured land, buildings, and plant equipment to operate battery recycling plants in Spain.

Zero Carbon Technologies Limited (ZCT) is setting an ambitious and impactful agenda with its plans to operate battery recycling plants in Spain. By focusing on Montalbo and Puertollano, the company aims to address critical issues in the recycling of EV batteries, such as lithium-ion and lead batteries.

Here are some key aspects of the plan:

Location and Capacity:

Montalbo and Puertollano: Both locations in the province of La Mancha, Spain, are chosen for their strategic advantages, including logistics, availability of resources, and regulatory support.

Throughput Goal: By Year 3, the combined capacity is projected to handle 75,000 tons of batteries annually, equivalent to approximately 1.5 million used batteries per year.

Recycling Focus:

Circular Critical Metals Recovery: ZCT is targeting the recovery of essential metals from EV batteries, which is crucial for the sustainability of the EV industry and the reduction of environmental impact.

Environmental Impact:

Zero Carbon Commitment: The company’s name and goals represent a strong focus on minimizing its carbon footprint, aligning with broader environmental objectives and the circular economy.

CREATING IMPACT

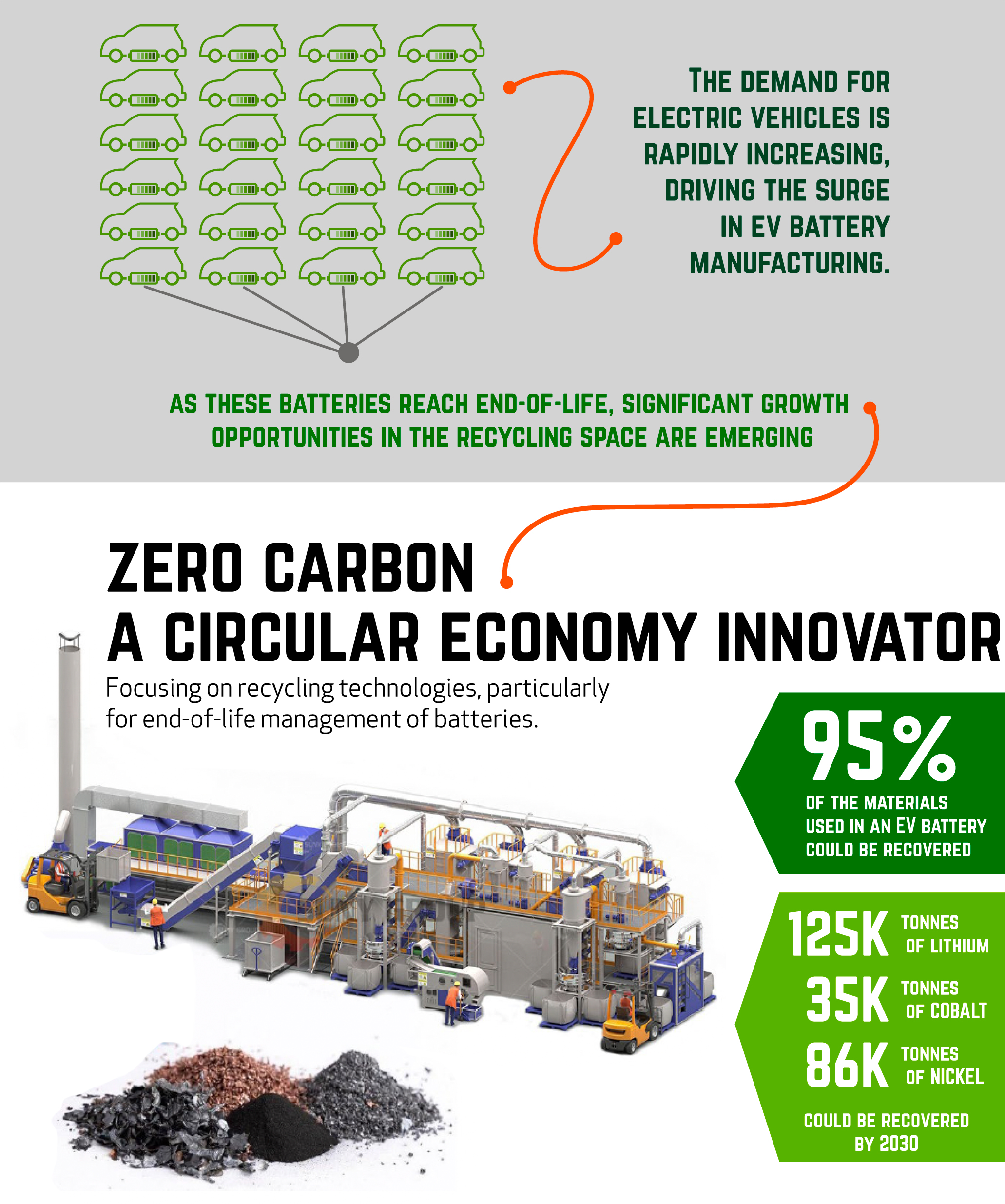

The use of batteries in electric vehicles is vital for a sustainable transportation system and achieving long-term climate goals. With the increasing demand for electric vehicles, there is also a growing need for EV batteries. As these batteries reach the end of their life, the recycling sector presents significant growth opportunities. Zero Carbon has developed patented and proprietary low-CO2 battery recycling solutions that enable over 80% of the battery and 95% of valuable metals to be recycled.

OUR MISSION

To Revolutionize Recycling

Connect a web of industries where one stream’s waste is another stream’s in-feed by bridging linear and wasteful processes to create a circular, pollution-free, zero-waste future.

CREATING A CIRCULAR, EMISSION-FREE AND ZERO WASTE FUTURE

THE PROBLEM

EVs may be more than 60% of all vehicles with over 300 million electric vehicles on the world’s roads by 2030.

International Energy Agency

The entire lithium-ion (Li-ion) battery chain, from mining through recycling, could grow by over 30 percent annually from 2022 to 2030.

American Chemical Society

In hard rock mining, for every ton of mined lithium, 15 tons of CO2are emitted into the air.

MIT Climate Portal

Only 5% of lithium-ion batteries are recycled

There are dramatic environmental and financial implications for the projected 8 million tons of waste.

CAS Science Team

NECESSITY FOR A CIRCULAR ECONOMY

Governments and the EU are mandating a more environmentally protective position to their industrial undertakings. In order to preserve critical metals, a recycling plan includes a focus on a circular economy.

140 million

The number of electric vehicles predicted to be on the road worldwide by 2030

11 million

Metric tons of Li-ion batteries expected to reach the end of their service lives between now and 2030

30–40%

The percentage of a Li-ion battery’s weight that comes from valuable cathode material

<5%

The percentage of Li-ion batteries that are recycled currently

100%

The percentage of the lead in common lead-acid car batteries that gets recycled into new batteries

$100 Billion

Global battery recycling market revenues by 2040

Source: https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/battery-recycling-takes-the-drivers-seat

FROM BATTERY PACK TO BLACK MASS

Zero Carbon’s advanced system, can recover 95% of the materials used in an EV battery including plastics, copper, aluminum, and the “black mass,” a powder containing the various elements inside Lead & Lithium-ion batteries & nickel, manganese, cobalt. Perfected through in-house engineering and collaboration with its technology partner REGENERATE (based in Nevada, USA, and Cambridge, UK), offers swift manufacturing, installation, and commissioning, all achievable within a span of just nine months from the date of instruction.